Rock chips cost. We have an easy solution.

Subtly stand out with premium paint-saving guards.

WHAT DO THEY DO?

-

Hate the splatter? So do we.

Rock chips, mud, dirt, and salty slush are an eyesore and ruin vehicle paint over time.

-

Effective designs, nothing more.

Our guards seamlessly blend in with each vehicle as if they came on the car from the factory.

-

Made in the USA.

Guard material and equipment are USA-sourced, with manufacturing and distribution based in Chicago, IL.

Megachip design cycle:

Step 1: Generate a 3D scan

Each vehicle requires unique guard shapes, mounting points, and simulations.

This BMW M5 scan shows details where the guards will attach.

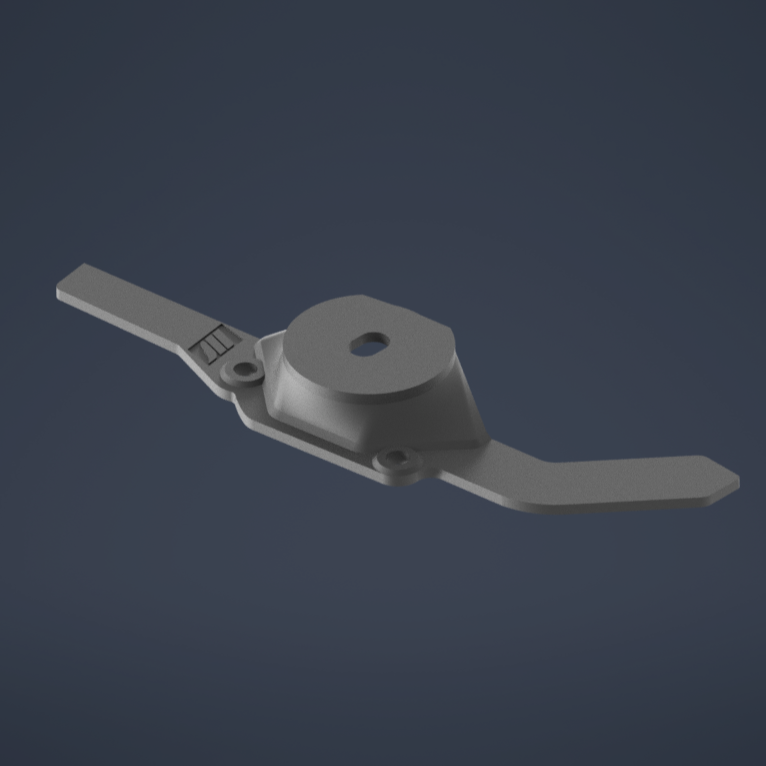

Step 2: Guard design

The shape of the guard is influenced by vehicle styling, wheel well shape, and CFD (aerodynamic) testing for our carbon fiber products.

Prototype guards are 3D-printed and mounted to the car for testing.

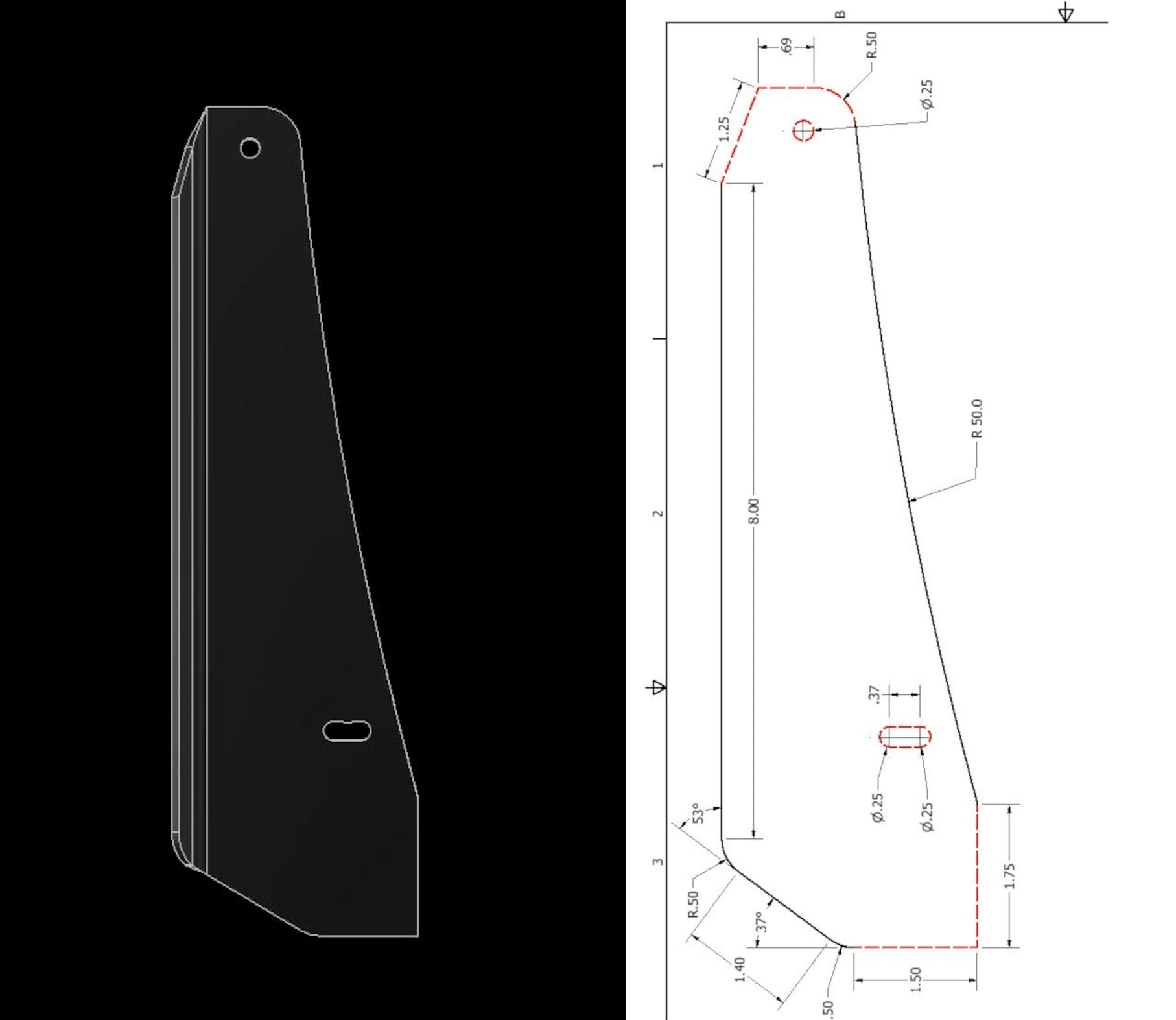

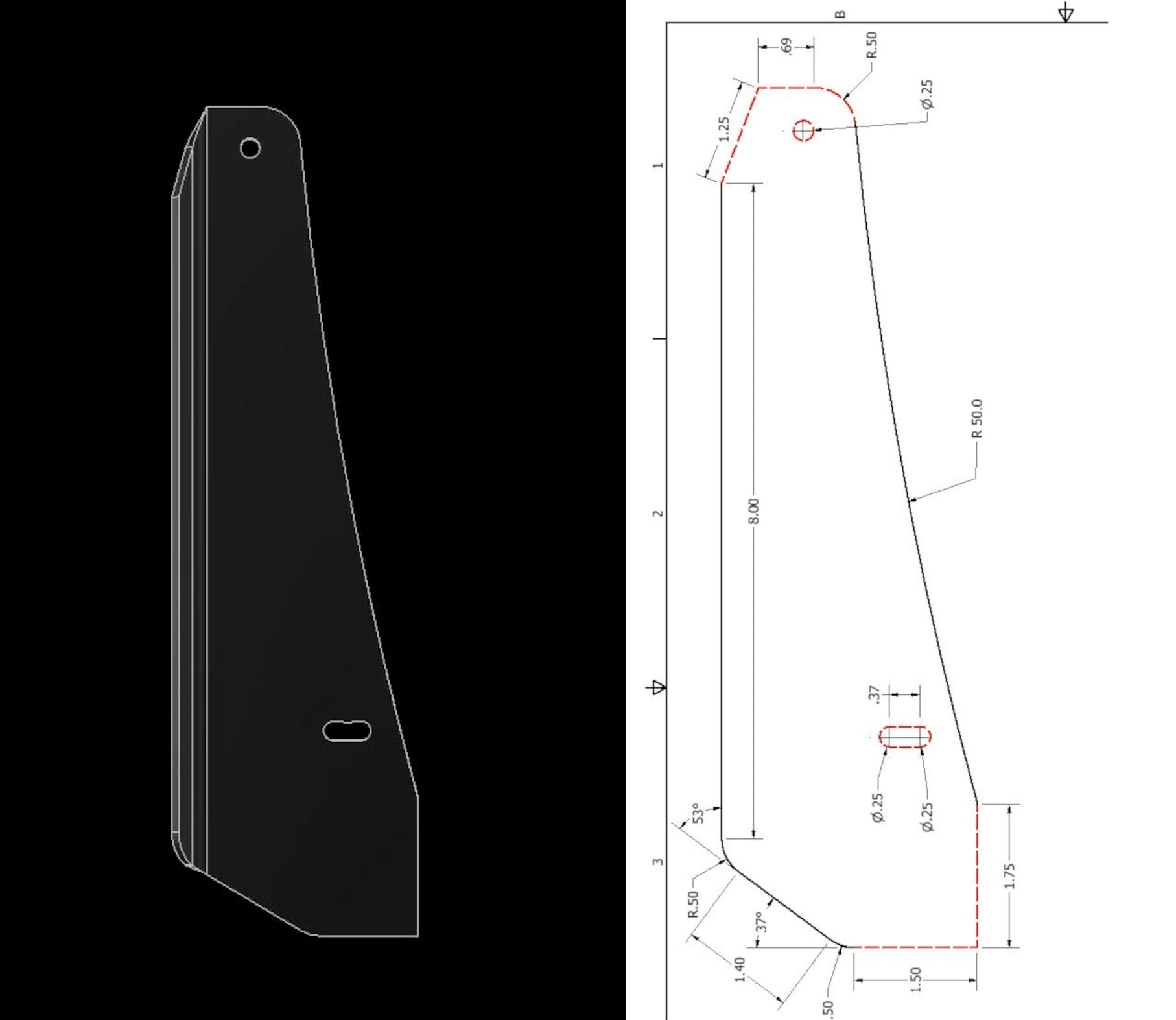

Step 3: Bracket design

This is the longest step in the development process. Our engineer designs the shape of brackets and mounting hardware to be simple, strong, and easy to install.

Step 4: Make 'em for real

Once we have a final design, drawings are submitted to our tooling manufacturer in Milwaukee, Wisconsin for forming the rubber guards.

After we receive the tooling, the guards are made and packed in Lake Zurich, Illinois.

Step 5: Paint gets saved

Countless rock chips are prevented every day on our customer's cars.

We take pride in designing products that are practical, well-made and well-engineered.

Minimize the footprint, maximize the effectiveness

Great materials meet great designs. Over 7000 cars are protected by our advanced splash guards.

What else do you wanna know?

What are the guards made of?

All original Megachip guards use a flexible foamed rubber-vinyl blend. The back side is vulcanized for a smooth finish, while the tire-facing side has a rough surface for a consistent appearance even after years of abuse from road debris.

All brackets and hardware are 3D-printed ASA, a durable plastic prepared for extreme outdoor conditions and impact from rocks.

Why do you use 3M™ adhesive for mounting?

3M™ VHB™ tape creates a strong, permanent bond without the need for drilling or modifying the vehicle.

There is no damage caused by the mounting process. After installation, the VHB 5952 tape bonds exceptionally well to the vehicle plastics, painted surfaces, and rubber guard material, in all weather conditions.

Can you drive through a car wash with these? What about pressure washers?

Yes. With proper installation, we guarantee the guards will stay attached to the vehicle in all situations except contact with large road debris and crashes.

Do these work in cold, snowy Winter conditions?

Absolutely. With six years and counting, Megachip guards have been put to the test through harsh Midwest winters, and satisfied many customers who experience extremely cold conditions.

Do you ship internationally?

Yes. We have affordable international shipping rates thanks to a special discounted shipping program. 15% of our customer base is international!

Do you offer a warranty?

We offer a one-year money back/exchange window and will work with you to resolve any issues after that period. Rarely, a customer may lose a single guard in a car accident, a repair shop removing one and not replacing it, or a poor installation. We ensure customer satisfaction and will help you resolve any issues. Please email us at sales@MegachipUSA.com

PICK YOUR CAR:

-

2015-2021 Subaru WRX / STI Guards

Regular price $89.99Regular price -

2016-2021 Honda Civic (10th-gen) Guards

Regular price $89.99Regular price -

2019-2022 Hyundai Veloster N Guards

Regular price $99.99Regular price -

2021+ Toyota GR86 / Subaru BRZ Splash Guards

Regular price $139.99Regular price -

2021-2023 Hyundai Kona N

Regular price $99.99Regular price -

2022+ Audi RS3 Guards

Regular price $149.99Regular price -

2022+ Civic (Non-Type R) Splash Guards

Regular price $89.99Regular price -

2022+ Subaru WRX Guards

Regular price $99.99Regular price -

2022+ Volkswagen GTI and Golf R (MK8) Splash Guards

Regular price $109.99Regular price